311th,OPPO Find X3 series officially released,In addition to the first time in the industry, 10-bit shots will be taken through、coding、store、decoding、Show the whole process,What is most impressive is its iconic appearance。The back of the Find X3 series adopts an "impossible" integrated surface design,A full sense of futuristic。

The back of the Find X3 series adopts continuous curved design,Integrated streamlined curved body,Integrated "Craft Mountain" design with lens,The entire image module is integrated with the entire back cover without any break points。Unseen continuous surfaces not only bring unique recognition,It also makes the grip of the whole machine feel better,The camera and rear cover transition area also avoid the trouble of dust accumulation。

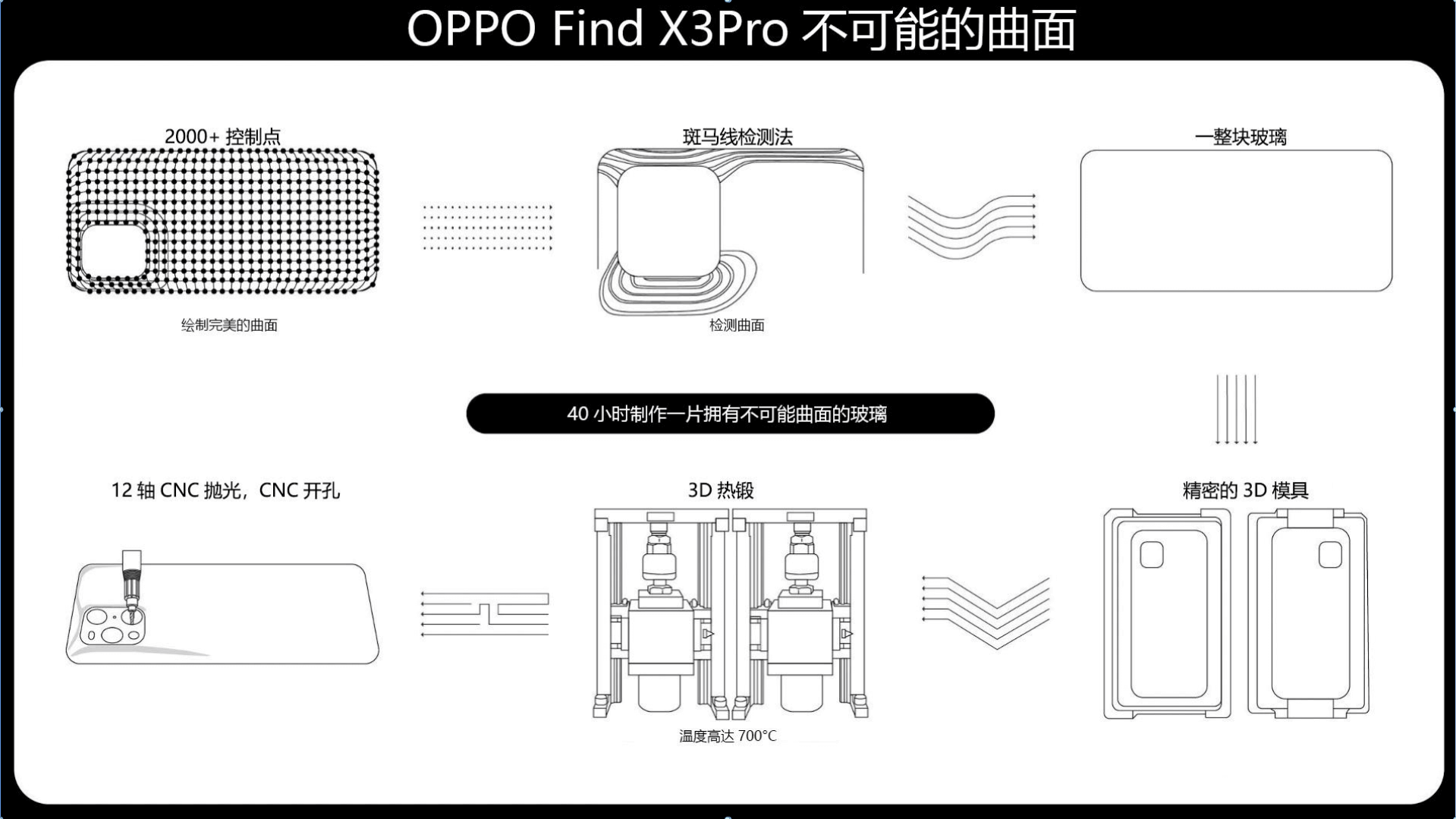

In the past mobile phone manufacturing,Such a integrated glass back panel will become almost impossible to produce due to the extremely difficult and cost in manufacturing.。This time, OPPO also overcomes many difficulties in the manufacturing of this back plate on the OPPO Find X3 series.,This "impossible surface" has become possible。

On this small glass back panel,More than two thousand positioning points are required to be precisely positioned,And hot-pressed forging this piece of glass in high temperature,Create a perfect curved transition。After light and heat,This glass back cover also requires high-precision CNC drilling,And perform a series of complex operations such as COC spraying and coloring,High difficulty up to 40 hours、High cost manufacturing,Just to present an "impossible surface" to the user。

Although it is difficult to achieve seamless connection between irregular arc surfaces and flat parts due to traditional processes,Potentially pitted、Breakpoint,Basically not mass-producible,But in order to achieve the integration of the back curve of Find X3 Pro,Still through more than 2,000 control points and complex hot forging forming process,Break through the yield and cost limits,Achieves the perfect transition between the lens and the body。

also,Find X3 series mirror black version introduces OC0 process for the first time,Glass with the glaze of ceramic,And the appearance is increased by coating,Combined with colored ink,Together enhance color and texture,Make the color more profound,At the same time, it feels more gentle.。

Fog blue and whitening adopt a new generation of light-matte integrated technology,The shiny crater lens has a lighter and transparent visual effect,The matte dividing line looks quite straight、Exquisite。

A new coating process combined with matte texture,Make the color purer,It brings a silky touch while,It can also achieve better anti-fingerprint effect。in addition,The OPPO Find X3 series is also a 193g/8.26mm thin flagship,The transition between the front and rear surfaces is also very natural,Round and comfortable holding。

visible,OPPO is not afraid of technical challenges and production capacity pressure on Find X3 series,Use cutting-edge technology in the industry,Bring us a flagship phone with futuristic aesthetics and ultimate feel,This exquisite feeling that makes people love is very worth experiencing at offline stores。

Related Reading:

OPPO Find X3 Pro gaming experience is extraordinary:Software and hardware complement each other

OPPO Find X3 Pro Imaging System Review

What upgrades can full-link color 10bit bring to the mobile phone experience?

OPPO Find X3 series officially released,Use full link color management system,Realized 10bit color depth